Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

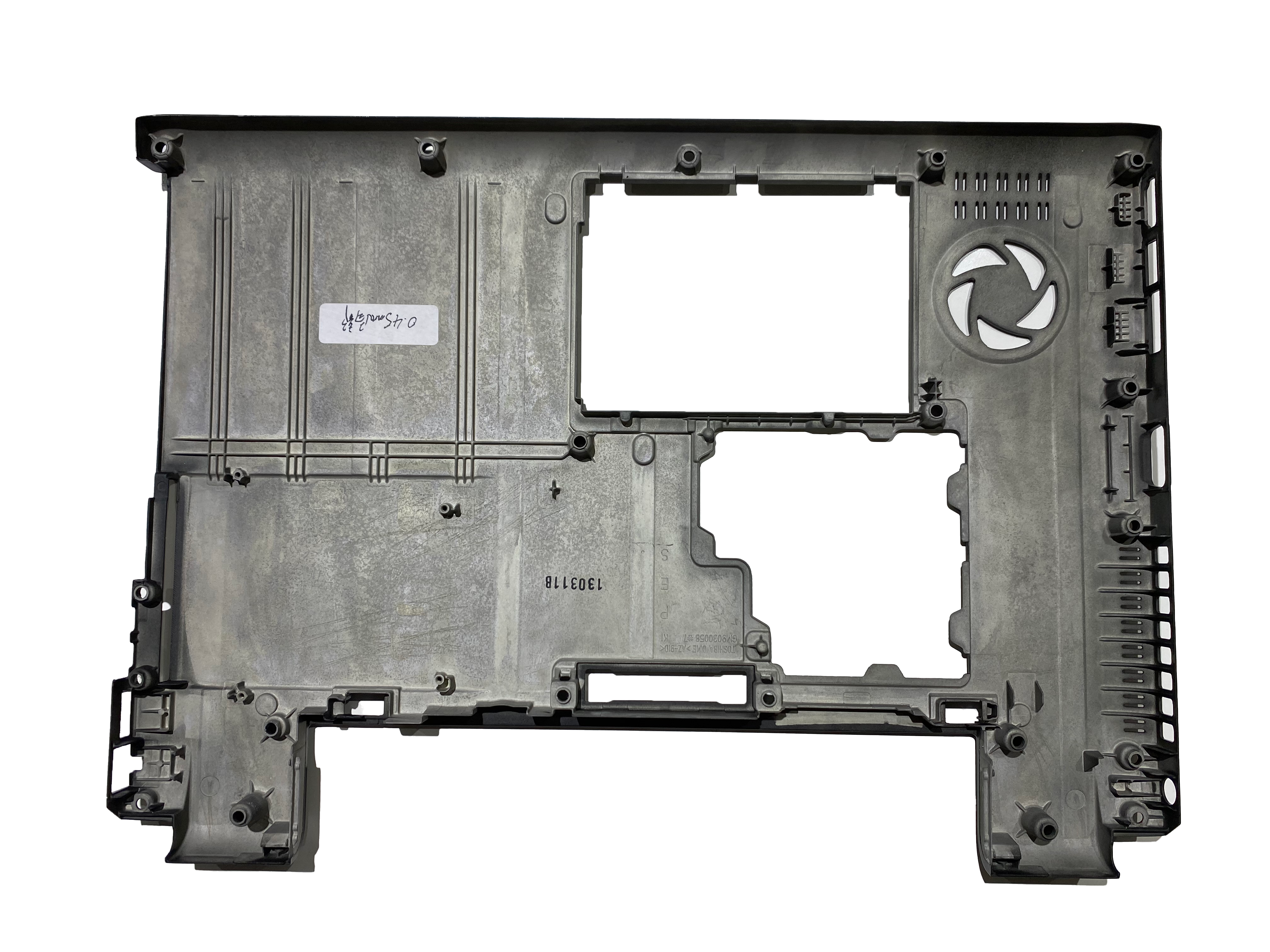

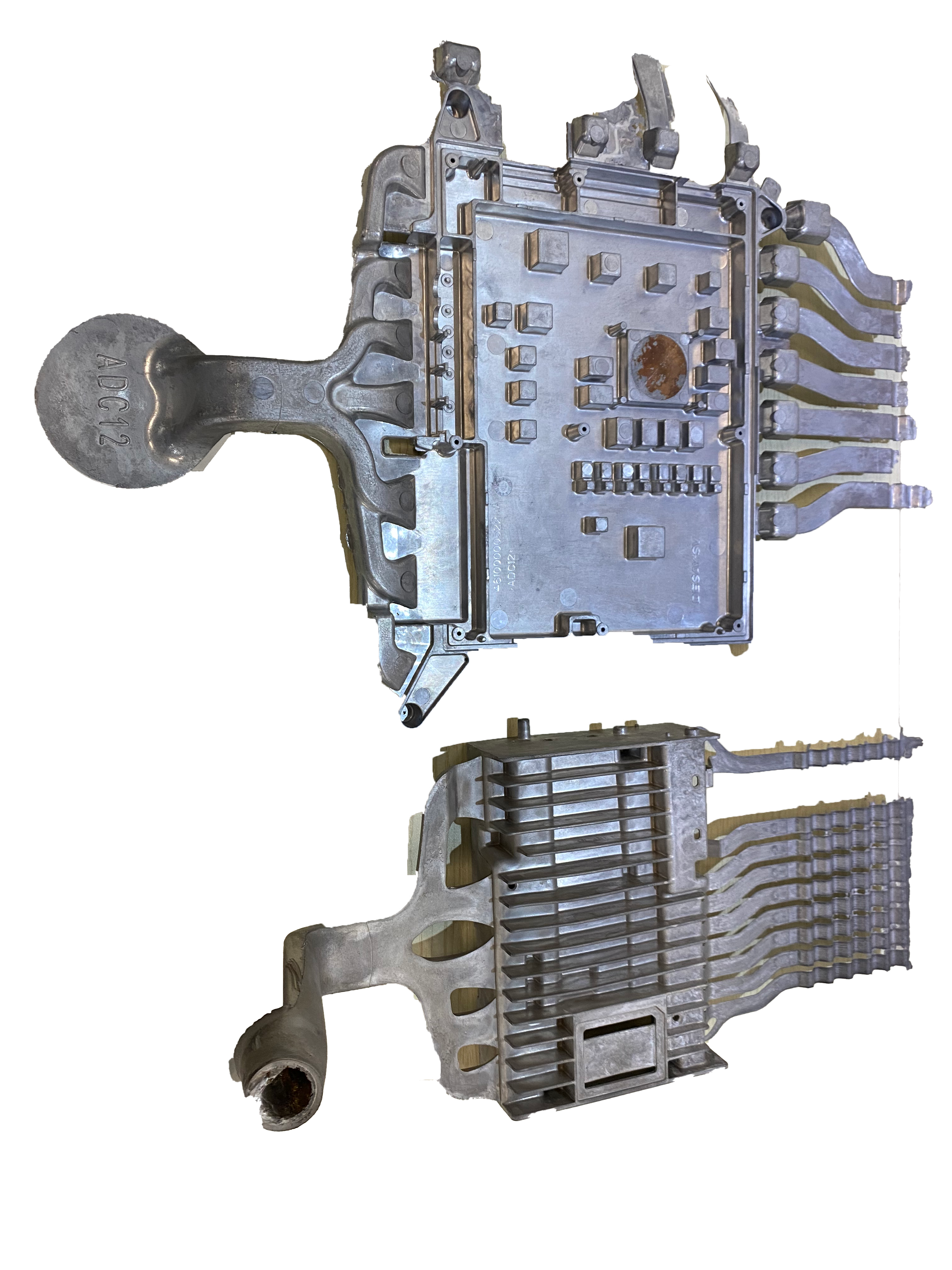

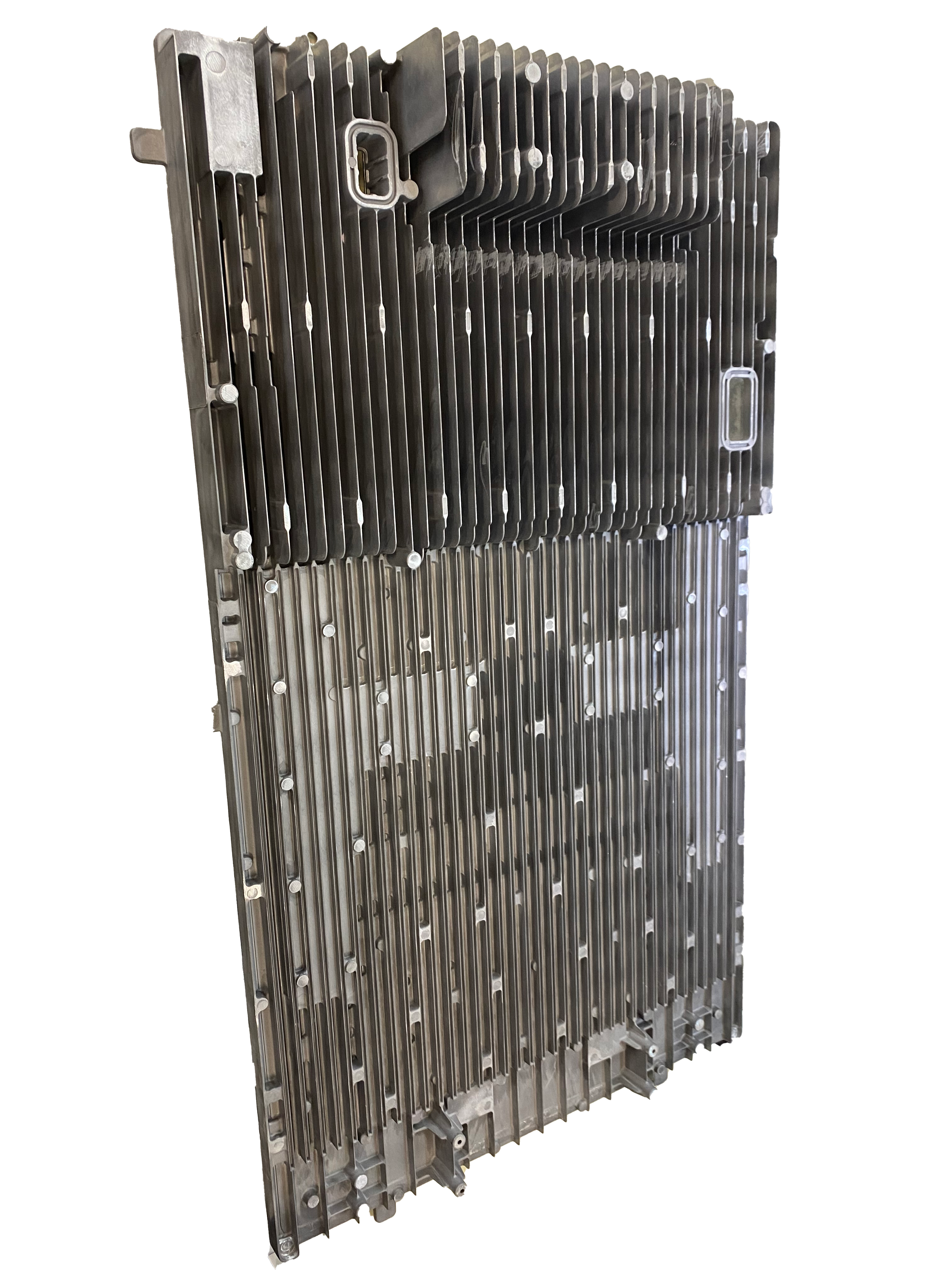

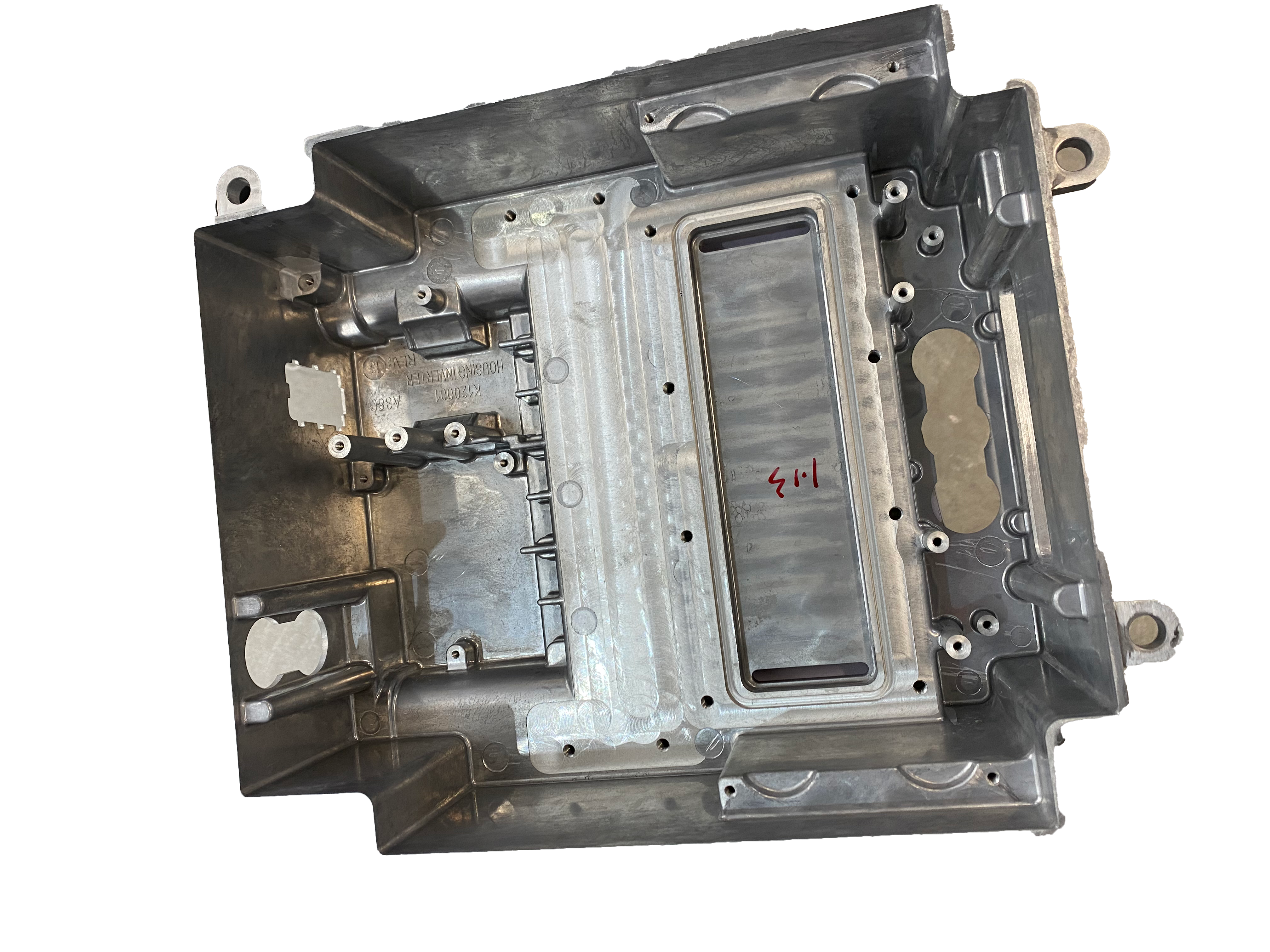

Die casting

There are numerous process methods used to transform metal materials into the necessary products, including casting, forging, extrusion, rolling, drawing, stamping, cutting, powder metallurgy, and others. The most fundamental, widely utilized, and extensive process method among them is casting. Casting involves pouring molten metal into a hollow mold constructed of materials that can withstand high temperatures, and after condensation, the result is formed with the desired shape.

Descriptions of Gravity Casting

To make metal materials into required products has a lot of process methods, like casting, forging, extrusion, rolling, drawing, stamping, cutting, powder metallurgy and so on. Among them, casting is the most basic, commonly used and extensive process method.

Pouring molten metal into a hollow mold made of high temperature resistant materials, and then the product with the desired shape is obtained after condensation, which is casting process.

Casting can be divided into ferrous metal casting (including cast iron, cast steel) and non-ferrous metal casting (including aluminum alloy, copper alloy, zinc alloy, magnesium alloy, etc.) according to the material of the casting. The non-ferrous precision casting factory specializes in non-ferrous metal casting, focusing on aluminum alloy and zinc alloy casting.

Casting can be divided into sand casting and metal casting in terms of the material of the casting mold. Minghe Precision Casting Factory is very good at these two casting processes, and designs and manufactures these two types of casting molds by itself.

Casting can also be divided into gravity casting and pressure casting according to the pouring process of molten metal. Gravity casting refers to the process of injecting molten metal into a mold under the action of the earth's gravity, also known as gravity casting. The generalized gravity casting includes sand casting, metal casting, investment casting, lost foam casting, mud casting, etc. The narrow gravity casting mainly refers to metal casting.

With decades of years in the gravity casting industry, Minghe gravity casting services

can meet the requirements of customers during the production of high-volume & low-cost casting parts. We can handled tailored gravity castings with simple or complex shapes at our factory. Endless gravity casting possibilities are allowed. Once you selected us, our engineers will start with understanding your demands, select the gravity casting design suits the application, figure out the gravity casting shapes, dimensions, specifications, tolerances, and all of the details before production. We have professional operators in the workshop to carry out each operation in a correct way to guarantee the products to meet or exceed international standards and customer expectations. Strong, lightweight, and corrosion-resistant casting products can be obtained by a fast and efficient gravity casting process.

FAQ

How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing(IGS or STP format). Second, Our engineers will check the drawing carefully and then provide you a better price. Thirdly, If you accept, then order confirmed.

Where is your factory?

Our factory located on Dongguan which is a beautiful city which is very near Guangzhou and Shenzhen. You can fly to Shenzhen Bao'an International Airport (ZGSZ) or Guangzhou Baiyun International Airport (ZGGG), we will pick you up at the airport.

Are you a factory or trade company?

We are a factory. We provide you one-stop service, from mold design to finish part.

How to ship?

The sample of die casting and CNC machining or small order is usually sent by TNT, FEDEX, UPS etc, and the big order is sent by air or sea after confirmation of clients.

What is your terms of payment ?

Die casting mould payments: advanced payment 40% after contract signing;

The 60% balance will be paid after approval of mould by customer.

The payment term of die casting orders: T/T, 30% as deposit be paid before production by T/T, 70% be paid before delivery.